Tankless Water Heaters: Efficiency Gains Come With Infrastructure Tradeoffs

Tankless water heaters can deliver efficiency and space savings, but higher utility demands and maintenance needs make careful planning essential.

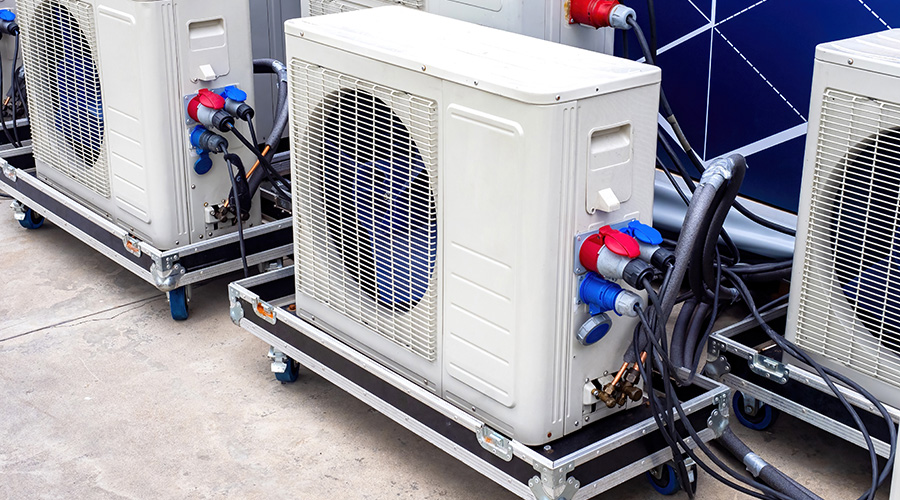

While tankless systems can reduce energy waste over time, they typically require higher peak utility input. Because water is heated on demand, gas or electrical utilities might need to be upgraded, particularly in retrofit projects.

“A tankless system might save energy annually, but it draws a lot of power in the moment,” Kleinschmidt says. “Step one is to determine what is really powering your water heating system. Is it all electric? Is it steam-based? Is it natural gas? Understanding what’s powering your current system is the first step in determining feasibility.”

In all-electric buildings, he says instantaneous demand can be a significant challenge.

“A lot of electrical power is needed for on-demand heating, and that can get very pricey, very quickly,” he says. “All electric is something we would recommend staying away from when doing tankless. We recommend a tank in that situation. But if you have natural gas or steam or even a hydronic system, it’s a great opportunity to use tankless water heaters because you can get on-demand heating at a very efficient and cost-effective level.”

Brummet says utility limitations are frequently the deciding factor. The energy used by tankless units can be higher than their tank-type counterparts, she says. For instance, a system with a 60-gallon tank and a 60-Mbh gas heater requires three gas-fired tankless water heaters, each with an input of 199 Mbh.

“That’s a considerable utility difference,” she says. “And that can be prohibitive in some projects.”

The location of the mechanical room can also limit the project, she says.

“The cost of bringing additional gas or electrical capacity into a mechanical room, especially one located deep within an existing building, can completely offset the projected energy savings,” she says. “Every project has to be evaluated individually, considering utilities, water quality and venting needs.”

Space savings

One visible advantage of tankless systems is their compact footprint. Wall-mounted units can replace large storage tanks, freeing up valuable mechanical room space.

“In existing buildings, space is often the biggest constraint,” Kleinschmidt says. “To be able to go with a more compact tankless model can be a huge differentiator. You can fit equipment into the mechanical room and be able to move around it to maintain it and access other equipment.”

But the space savings might be offset by the need for additional equipment. Tankless systems can be very sensitive to water quality, requiring facilities to install water softening or filtration systems.

“It’s not a magic fix,” Brummet says. “You might remove tanks, but you may need to reallocate that space for water treatment.”

Maintenance matters

Maintenance also is a critical consideration for tankless systems. While all domestic hot water equipment requires routine service, tankless systems are less forgiving when maintenance is delayed.

“These units require periodic descaling and flushing,” Brummet says.

Adds Kleinschmidt, “With tankless, the heat exchanger is the only source of hot water. If it’s fouled or scaled, performance drops immediately.”

Without stored hot water as a buffer, scale buildup can affect occupant comfort and system reliability. Equipment to soften hard water could be necessary to stop further corrosion.

“Preventive maintenance isn’t optional with tankless systems,” Brummet says. “In hard-water areas, facilities may need to descale every six months if water treatment isn’t in place.”

Maintenance also should be scheduled, which requires preparation and planning. Manifolded tankless systems can minimize maintenance’s effect on building operations and permit individual units to be isolated and maintained without a full system shutdown.

Kleinschmidt says a well-maintained tankless system will last 15 to 20 years but adds, “Water quality matters, conditions matter, and how it gets maintained matters. But overall, we’ve seen tankless systems operate pretty well long term.”

Reliability through redundancy

For facilities where uninterrupted hot water is critical, redundancy is a key design principle.

“Our recommendation is always to include redundancy,” Kleinschmidt says. “If it takes three units to meet demand, we often recommend installing a fourth identical unit, so maintenance or failure doesn’t reduce capacity.”

Brummet says redundancy becomes increasingly important in mission-critical environments.

“In healthcare or large hospitality facilities, we may intentionally oversize the system,” she says. “The goal is to ensure there’s never a single point of failure.”

Tankless water heaters should be evaluated as part of a broader domestic hot water strategy rather than as a one-for-one replacement, Kleinschmidt says.

“It’s not just about first cost or operating cost,” he says. “It’s about understanding the blend of both, along with maintenance, replacement and long-term reliability.”

Brummet agrees.

“When tankless systems are designed thoughtfully, they give facility managers flexibility,” she says. “You’re managing a group of assets instead of a single point of failure, and that can be a powerful advantage.”

With the evolution of the Internet of Things and building management controls, managers will be able to remotely diagnose tankless systems and harvest data that can be leveraged to reduce energy, spend maintenance dollars wisely and provide safe and reliable systems.

For instance, consider scale on heat exchangers. Managers can add flow sensors to track flow capacity.

“We could see exactly when flow starts to decrease and flag the tankless water heater for descaling,” Brummet says. “Actual maintenance is obviously a physical job, but logging and scheduling could happen automatically.”

Tankless water heaters are not one-size-fits-all technology, but for managers in facilities with the right load profiles and infrastructure, they can deliver meaningful benefits. Careful evaluation of utilities, demand patterns and maintenance capabilities is essential for the water heaters to align with long-term operational goals.

Ronnie Wendt is a freelance writer based in Minocqua, Wisconsin.

Related Topics: