SPONSORED

Cummins - Branded Feature

Specifying the Right Transfer Switch

Cummins

Transfer switch equipment is available in a variety of types, with a wide array of features. Selecting the appropriate transfer switch for a specific application requires a clear understanding of site needs and switch options. This paper discusses the key elements that must be considered when specifying a transfer switch, so that a more informed selection can be made.

Transfer switches are vital! They are 3rd party certified and at the heart of an emergency power system, providing a dependable power transfer between two power sources (a utility and an emergency standby generator, for example) and facility loads. When the normal power source fails, transfer switches detect the loss of power, send a start signal to the standby generator and then connect the generator to facility loads when the generator has reached proper voltage and frequency. When utility power is restored, the transfer switch returns the load from the emergency power source to the normal one.

In cases of utility failure when the emergency power source is not operating, power to facility loads will be lost for a period of approximately 10 seconds while the generator set starts — unless there is an Uninterruptible Power Supply (UPS) serving loads in the system to bridge the power gap while the generator set starts, reaches the proper voltage and frequency, and the automatic transfer switch transfers.

Considerations when selecting a transfer switch

When specifying a transfer switch for a power system, several factors impact the selection of the switch. Some of these factors are (along with some examples):

- Codes and standards (UL, CSA, NFPA, NEMA, IBC, OSHPD)

- Application (utility-to-generator, generator-togenerator, utility-to-utility)

- Transition type (open, closed, non-automatic)

- Switch positions (2-positions, 3-positions)

- Number of poles (3-pole, 4-pole)

- Separately derived or non-separately derived

- Service-entrance or non-service-entrance

- Switch type (transfer switch, bypass isolation switch)

- Voltage and frequency (600VAC, 480VAC/50Hz, 60Hz)

- Current rating

- Fault current capability (WCR*)

- Short-time fault current capability (WCR*)

- Selective coordination (WCR & listed OCPD**)

- Cable lugs and entry requirements (compression/mechanical, top/bottom entry)

- Enclosures (NEMA Type 1, 3R, 4, 4x, 12)

Codes and Standards

Transfer switches are designed to meet the leading testing requirements specified by UL 1008 “Standard for Safety - Transfer Switch Equipment.” UL 1008 specifies robust and rigorous testing requirements for verifying manufacturer ratings and ensure reliability and durability. UL 1008 is harmonized with the Canadian standard CSA C22.2 No.178.1. Any transfer switch product listed as such is suitable for use in any application in North America. Transfer switch products without these listing can be challenged in some marketplaces and applications.

Transfer switches are applied in a variety of applications that typically fall into one of four categories defined by the National Electrical Code® (NFPA 70®): emergency systems, legally required systems, optional standby systems, and critical operations power systems. Understanding those categories is important, as they play a critical role in determining what kind of transfer switch you require.

- Emergency systems (Article 700): Automatically supply, distribute, and control electricity used by systems essential to life safety during fires and other disasters.

They include fire detectors, alarms, emergency lights, elevators, fire pumps, public safety communication systems

- Legally required systems (Article 701): Automatically supply power to a selected set of regulated loads not classified as emergency systems when normal power is unavailable. They serve critical heating, refrigeration, communication, ventilation, and smoke removal

- Optional standby systems (Article 702): Supply power to loads with no direct bearing on health or life safety, and are not required to function automatically during power failures

- Critical operations power systems

(Article 708): Supply, distribute, and control electricity in designated critical areas when a normal power source fails. They include HVAC, fire alarm, security, communication, signaling, and other services in facilities that a government agency has deemed important to national security, the economy, or public health and safety

Another standard that impacts the selection of the transfer switch is NFPA 110® Standard for

Emergency and Standby Power Systems. The intent of NFPA 110® is to achieve maximum system

reliability. It covers installation, maintenance, operation, and testing requirements as they

pertain to the performance of the Emergency Power Supply System (EPSS). The requirements cover the performance of emergency and standby power systems providing an alternate source of electrical power to loads in buildings and facilities if the primary power source fails. The standard differentiates systems by Class, Type, and Level as follows:

- Class: The class defines the minimum time, in hours, for which the EPSS is designed to operate at its rated load without being refueled or recharged.

- Type: The type defines the maximum time, in seconds, that the EPSS will permit the load terminals of the transfer switch to be without acceptable electrical power

- Level: Level 1 and Level 2:

- Level 1 systems are installed where a failure of backup power could result in loss of human life or serious injuries.

- Level 2 systems serve systems and equipment that are “less critical” to human life and safety.

Therefore, a system requirement specifying NFPA 110®, Level 1, Type 10 for power system cannot be met with a manual transfer switch and an automatic transfer switch must be selected.

The additional codes to pay attention to are NFPA 70® Article 517, NFPA 99® for Healthcare, and OSHPD (Office of Statewide Health Planning and Development – Healthcare in California

which also include a seismic element). These standards call for a UL1008 automatic transfer switch for use in emergency systems and some require a bypass isolation transfer switch.

The International Building Code (IBC®) is another

code to consider when selecting and applying a

transfer switch in the power system. It is important

for standby power systems to function after a

catastrophic event, such as a hurricane, tornado,

or an earthquake. IBC® requires that critical

equipment, such as on-site power systems that

power critical branches such as hospitals, police

and fire stations, emergency shelters, power plants,

airports, government facilities, and communications

and operations centers, may need to endure higher

physical shocks and multi-axis accelerations in

certain areas of the United States, including those

generated near the San Andreas Fault in California.

All of the Cummins PowerCommand® X-Series

transfer switches are certified to IBC 2018, which

requires strenuous testing of the assembled

product to verify its ability to survive seismic events.

A variety of arrangements are available utilizing two power sources and three power sources when applying a

transfer switch in a power system:.

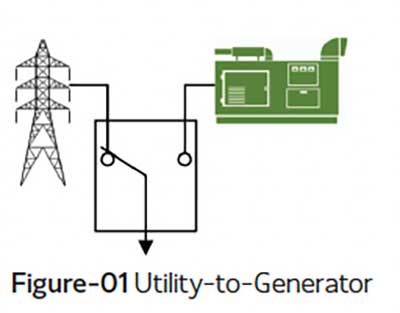

- Utility-to-generator

The most common application and it is typically referred to as

emergency standby generator system. The transfer switch

configuration includes a utility feed and a generator set for normal

and emergency power sources (see Figure-01).

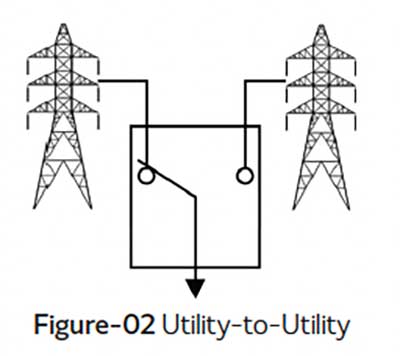

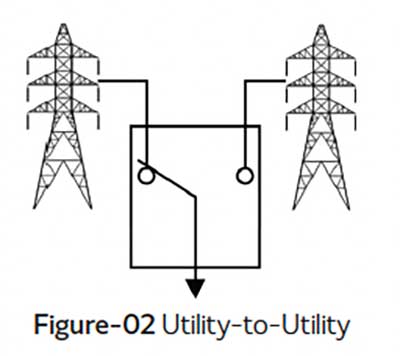

- Utility-to-utility:

In this configuration two utility sources provide redundancy in the

distribution system and allows for quick restoration of service to the

load if one utility source fails. The two sources can be independent

of each other, requiring the public utility company to provide dual

electric services, or they can originate from a single electric service

that is distributed through redundant paths within the facility (see

Figure-02).

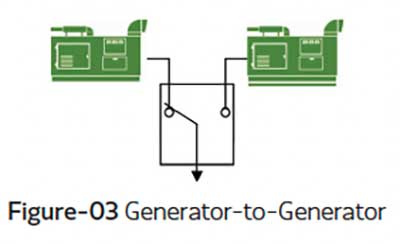

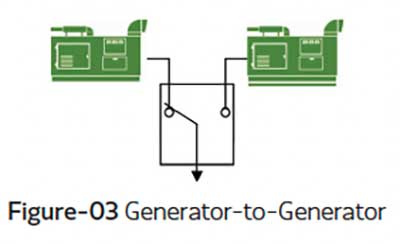

- Generator-to-generator:

The common use case is a prime power application, often at remote

installations. In such cases, the generator may be required to provide

continuous power to the facility loads. To equally share run-time,

source power is periodically swapped between the generator sets via

the transfer switch smart controls (see Figure-03).

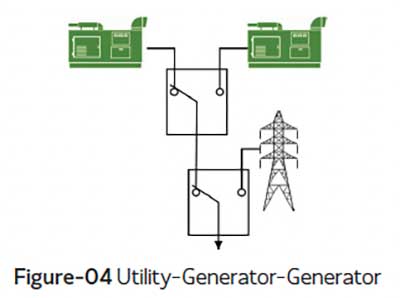

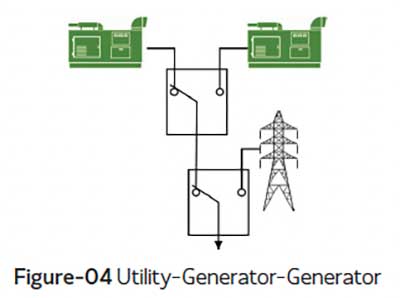

- Utility-generator-generator:

(also known as three power source)

Critical facilities with an emergency standby generator system will

often include provisions for a second generator connection to serve

as a redundant emergency backup that can be used during periods

of inclement weather, or when scheduled maintenance is being

performed on the first generator (see Figure-04).

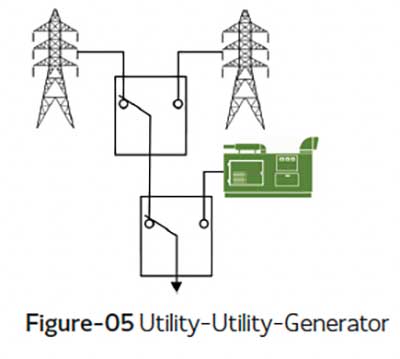

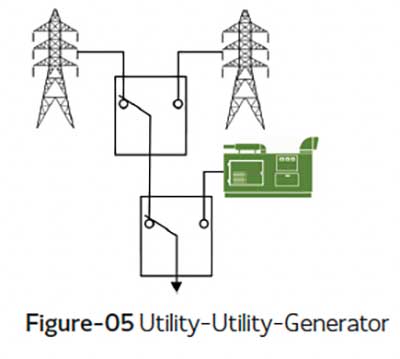

- Utility-utility-generator:

(also known as three power source)

This configuration expands on the redundancy provided by a dual

utility arrangement and includes an emergency standby generator

source (see Figure-05).

Transition type

Transfer switches transition facility loads between

two sources. The way the transition takes place

is known as the transition type. There are three

transition types discussed here: Automatic open

transition, Automatic hard-closed transition, and

Non-automatic transition

Automatic open transition:

Open-transition transfer switches provide a “break-before-make” switching action. They are specifically designed to transfer power between utility and onsite power systems. The connection to one source is opened before the connection to the second source is closed. Mechanical interlocks that positively prevent interconnection of sources are commonly used. Some manufacturers include electrical interlocks in addition to the mechanical interlocks. Open-transition transfer switches are the most commonly used type of transfer switch and are used in all types of applications. By design, they neither require nor allow generator set paralleling with the utility service.

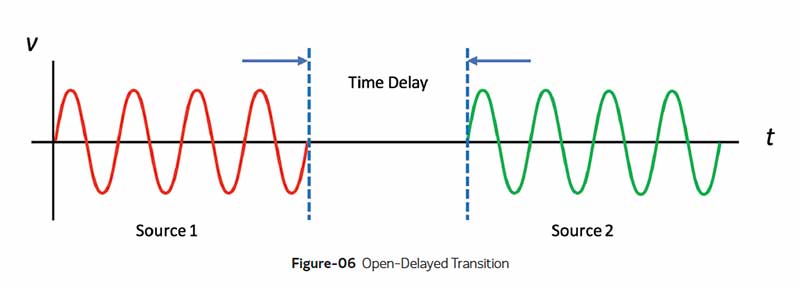

There are three types of open transition: opendelayed, open-fast-transition sync, or open-fast-transition no sync.

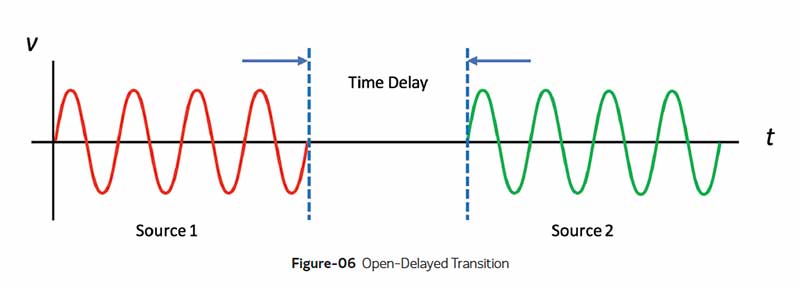

- Open-delayed transition

In an open-delayed transition, the transfer

switch pauses or stops in intermediate position for a pre-set amount of time disconnecting the load from both sources before connecting to the other available source (see Figure-06). Open-delayed transition requires a three-position transfer switch mechanism which is discussed in the next section.

The delay typically lasts a specific, pre-set amount of time. That time delay should be set to allow the voltage generated by the load to decay to a safe level before connecting to the available source. NEMA MG-1 recommends a delay of 1.5x Motor Open Circuit Time Constant. That brings the voltage generated by the load to 22% of nominal. Typical application for this kind of transition is stored energy loads such as inductive motors or MRI machines.

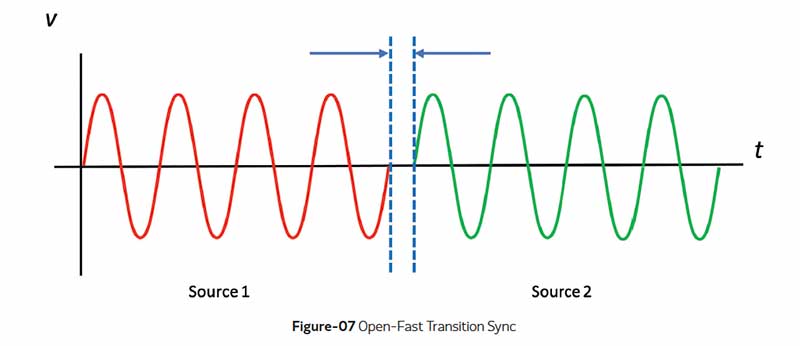

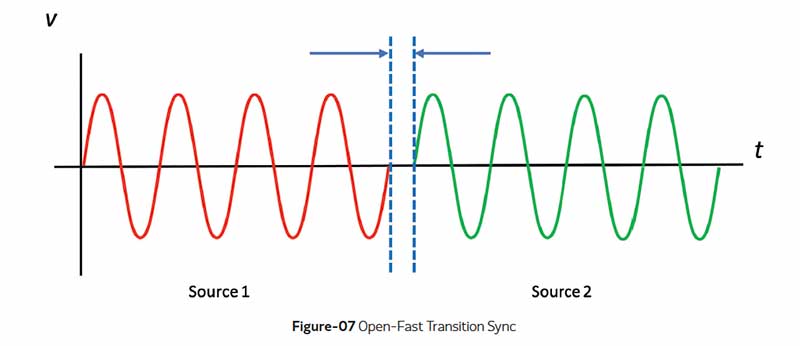

- Open-fast-transition sync:

This transition mode is also known as in-phase transition. In this transition mode, the transfer switch control uses built-in sophisticated algorithm to execute an open transition at the precise moment the normal and emergency power sources are synchronized phase, voltage, and frequency (see Figure-07). Transfer switch controls don’t include active synchronizers. The synchronizers are typically part of the generator integrated control.

Open-Fast-Transition Sync are typically completed in 100ms or less and there are no intentional time delays configured for this mode of transfer. Typical applications for this mode are small inductive loads less than 20hp and resistive loads.

Some transfer switch OEMs such as Cummins include a back-up if synchronization between the two sources doesn’t occur within a pre-set time span. In that event the switch control defaults to an opendelayed transition.

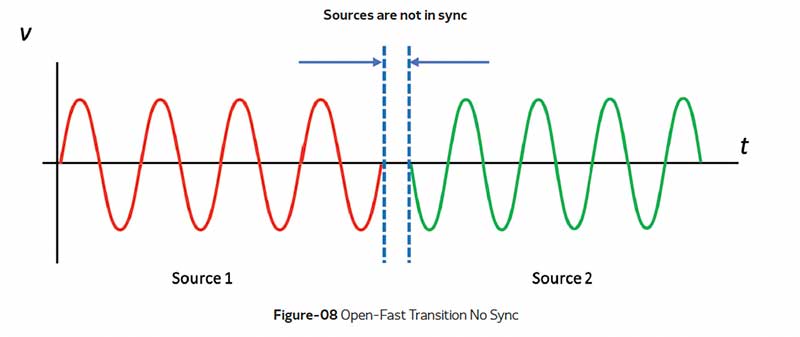

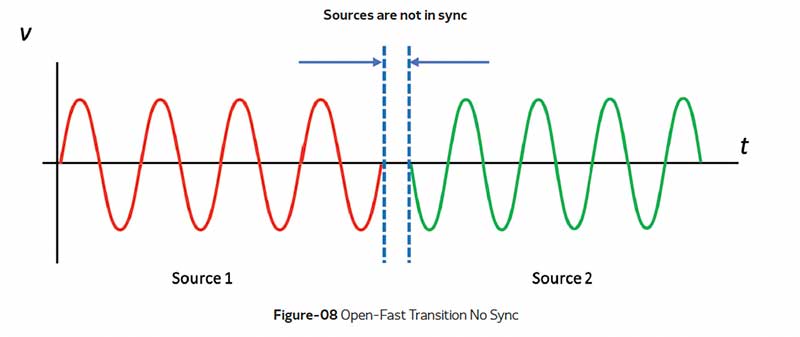

- Open-fast-transition no sync:

In this transition mode, there are no intentional time delays and no need to wait for the sources to be

synchronized before transferring (see Figure-08). Open-Fast-Transition No Sync are typically completed in 100ms or less. Typical applications for this mode are resistive loads.

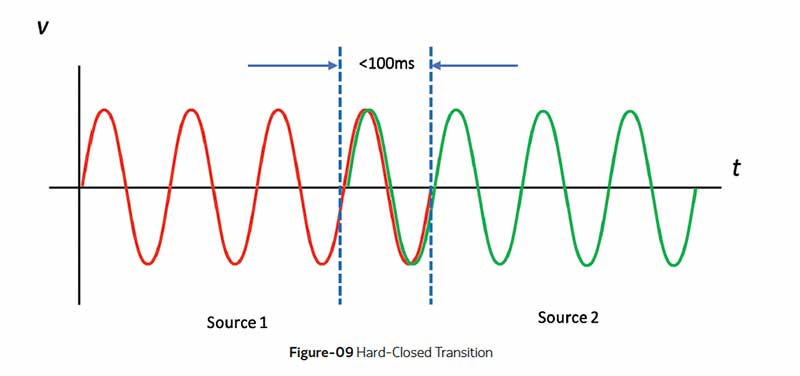

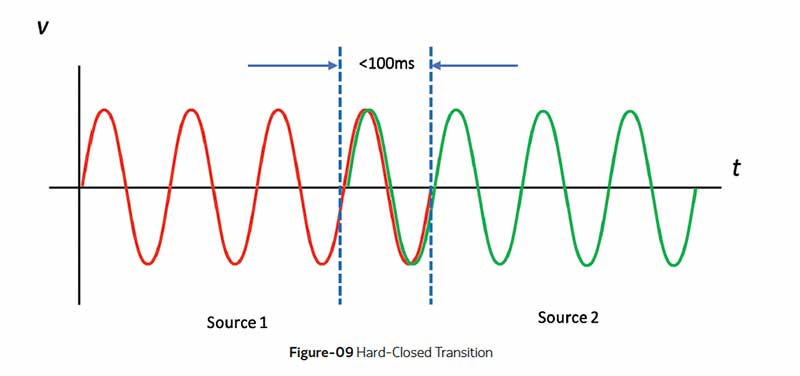

Automatic hard-closed transition:

Closed-transition transfer switches provide a “make-before-break” switching action and utilize a momentary paralleling of both sources (<100ms) during the transfer period, when both sources are available. Both sources must be synchronized (phase, voltage, and frequency) before momentary paralleling them (see Figure-09). Closed transition transfer switches do not include mechanical nor electrical interlocking of sources. Since there is no gap between disconnecting and connecting sources, downstream loads receive continuous power throughout the transfer process.

Some utilities require closed transitions to comply with interconnect requirements aimed at preserving power quality and protecting utility service personnel and equipment. In some cases, this can require the inclusion of protective relays in the electrical circuit such as:

- 62PL Parallel Timer (a timer relay that is independent and external to the transfer switch control which disconnects the site from the utility service if it does not disconnect as designed)

- 32R Reverse Power (directional power relay which disconnects the site from the utility service if power flows into the utility)

- 86LO Lockout (an electromechanical relay which latches its output contacts and prevents reconnection to the utility without intervention from the service supplier)

Always verify local service requirements when providing closed transition transfer switches for an application.

Non-automatic transition:

This transition mode also provides “break-before-make” switching action. The transfer between sources is manually initiated by an operator. All the time delays (transfer, re-transfer, elevator, program transition) and control protection are still active in this mode. The advantage of this mode is that the operators are in complete command of transfer initiation. But this advantage can be a disadvantage in some applications since an operator must be present to initiate a transfer. Also, in this transition mode, there’s neither support for openfast-transition sync (in-phase) nor closed transitions.

It is important to note that non-automatic is not the same as Manual Transfer Switch (MTS). Manual switches are manually controlled and require direct operation by a person to transfer the load. This operation is through a lever or a handle; the switch does not have electrically actuated solenoids, contactors, nor motors. The actual contact mechanisms are operated using spring energy in order to achieve a “quick” make or break of the current carrying contacts. These switches do not have monitoring capability for the power sources. Also, they contain a very rudimentary or no control system.

The NEC® requires automatic transfer switches for Emergency, Legally Required, and Critical Operation Power (Articles: 700/701/708). Manual and Non-Automatic are not permitted.

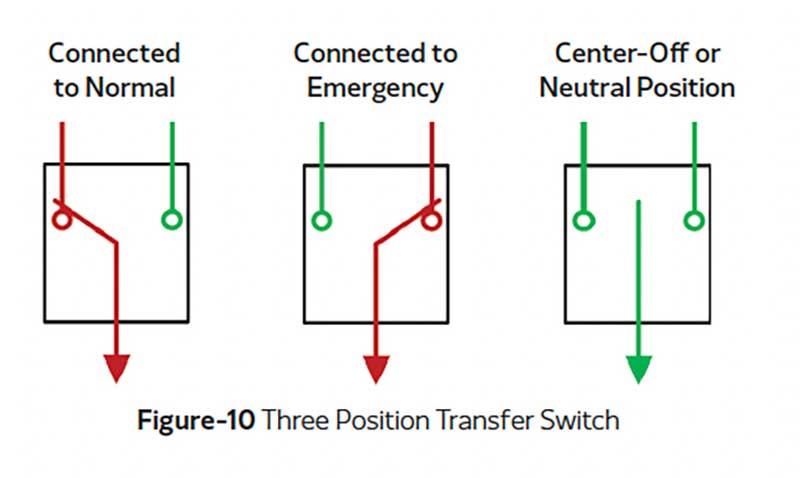

Switch positions

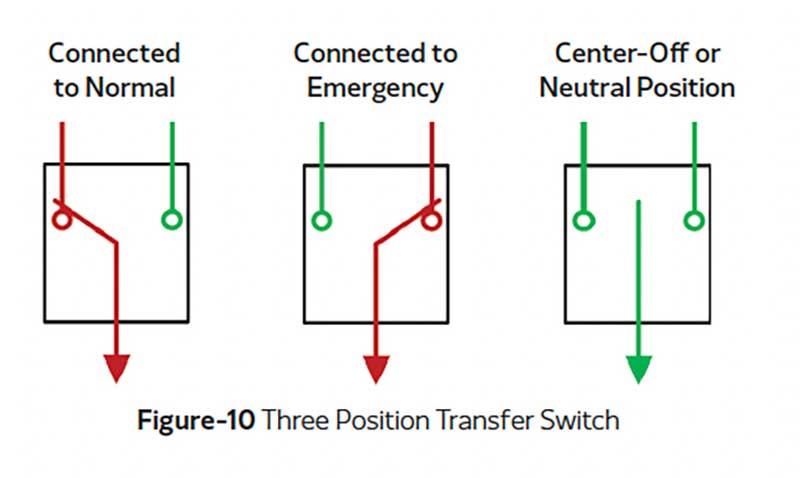

Switch position refers to which source the load is connected. In a 2-position switch, the load is either connected to the normal source or the emergency source. For residential applications, a 2-position transfer switch is a very economical solution.

In a 3-position switch, the load is either connected to the normal source or the emergency source, or it can be in a middle position known as center-off position (see Figure-10). The center-off position is also known as the neutral position. In the center-off position or neutral position, the load isn’t connected to either source. The applications for a 3-position switch are delayed-transition and load shedding. For example, if the load is connected to the emergency source and an overload condition occurs, the generator set control senses that overload condition, then sends a signal to the transfer switch causing it to shed and move to the neutral position. The load shed signal may come from the generator set control or in more complex operations the signal may come from a system level control. The advantage of a 3-position switch is disconnecting the load from the emergency source and staying in center off position. It is not recommended to shed load to a deenergized utility source.

Load shed maybe required by code. NEC® 2020 700.4 (C) allows the alternate power source to supply emergency, legally required, and optional system loads where the source has adequate capacity or where automatic selective load shed is provided as needed to ensure adequate power.

Number of poles

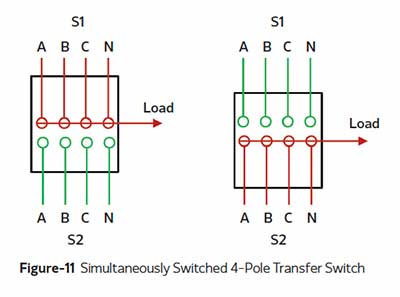

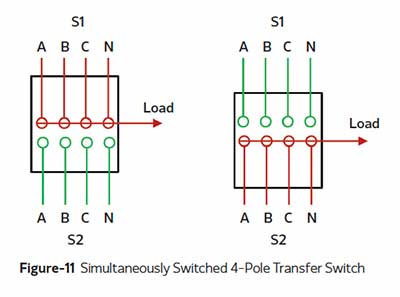

Transfer switches are offered in two configurations: a 3-pole (the mechanism switches the three phase poles A, B, and C. The neutral is solid) and 4-pole (the

mechanism switches the three phase poles A, B, C, and the neutral).

There are two methods of switching the neutral: simultaneous switching and overlapping neutral switching. With simultaneous switching, offered on Cummins switches, the neutral pole is mounted on a common crossbar with the phase poles, and thus, is switched at the same time as the phase conductors in a break-before-make action (see Figure-11). The grounded neutrals of the two power sources are not connected, even momentarily.

With overlapping switching, the neutral pole is momentarily closed to the grounded neutrals of both power sources in a make-before-break action. A temporary solid neutral connection is created with multiple grounds. Neutral current has, therefore, two paths of return to the source during the overlapping make-before-break switching action and a nuisance trip could result when no ground fault exists.

Overlapping neutral transfer switches have inherent failure modes which don’t exist in a simultaneously switched neutral product. Specifically, because the neutral pole operates independently of the phase poles, it could fail to transfer completely when the phase poles transfer. Two effects of this failure mode are that the neutral pole could be left disconnected

from both sources creating a floating neutral condition, and the neutral pole could be left connected to both sources creating two neutral to ground connections with the potential for ground loops and incorrect earth fault detection. Even with a properly functioning neutral pole there will be a period during transfer when two neutral to ground connections will exist.

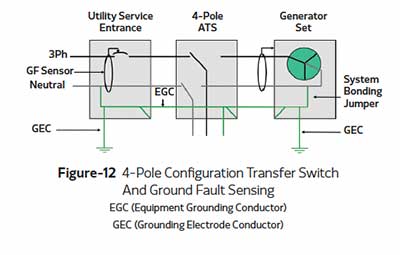

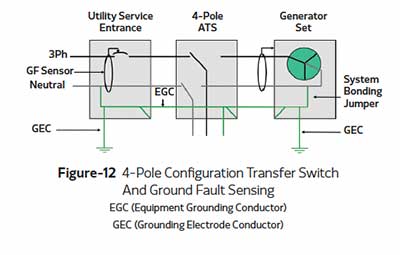

To determine which configuration (3-Pole or 4-Poles) to select, attention must be paid to

the system grounding scheme and ground fault protection requirements. If ground fault detection is required on either source, a 4-pole transfer switch is necessary in most cases. Per NEC® 230.95 Ground Fault Protection (GFP) of equipment is required at the service disconnect (utility breaker) for systems with all of the following:

- Solidly grounded wye electrical service

- More than 150 volts to ground (277/480 or

347/600VAC)

- Over current device rating of 1000A or more

NEC® 700.6 (D) and 701.6 (D) requires Ground Fault

Indication (GFI) at the emergency source.

Ground fault sensing depends on being able to sense

ground fault current. To accurately sense ground fault

current, it must return to its source on a known path

relative to ground fault current transformers (CTs). In

basic emergency standby systems there are two rules

to follow to meet these requirements:

- There can only be one neutral/ground connection

on any neutral bus at one time

- Ground fault sensors (the CTs) must be

downstream (or on the load side) of the bonding

connection

To meet both rules when connected to either the

normal or the emergency source, the neutral must be

switched using a 4-pole transfer switch (see Figure-12).

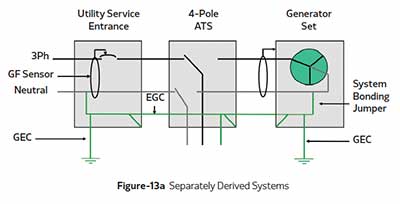

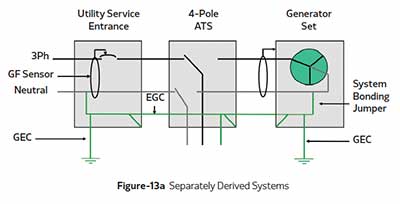

Separately derived or non-separately derived

The NEC® defines separately derived systems as “An electrical source, other than a service, having no direct

connection(s) to circuit conductors of any other electrical source other than those established by grounding and

bonding connections”. NEC Section 250.30(A)(1) requires separately derived systems to have a system bonding

jumper connected between the generator frame and the grounded circuit conductor (neutral).

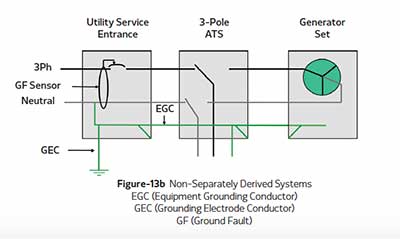

A switched neutral pole as shown in Figure-13a (refer to the previous section: Number of Poles) is used in

applications where it is necessary for accurate sensing of ground fault current. When used, the on-site

generator set is a separately derived system. Where the transfer equipment includes a switched neutral pole

and the generator is a separately derived system, its neutral must be bonded to an effective ground.

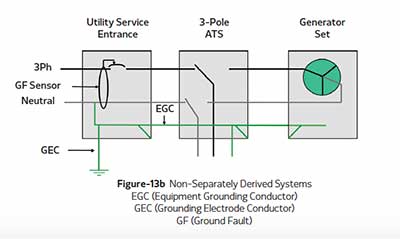

In the system shown in Figure-13b, the neutral conductor is grounded at the service equipment. Ground Fault

Protection (GFP) for equipment may be added to the normal service equipment. The only path for ground fault

current is on the grounding conductor outside of the GFP sensors. The generator neutral is not bonded to

ground, because to do so would create multiple ground fault current paths; one of which would be through the

sensor, the other outside the sensor.

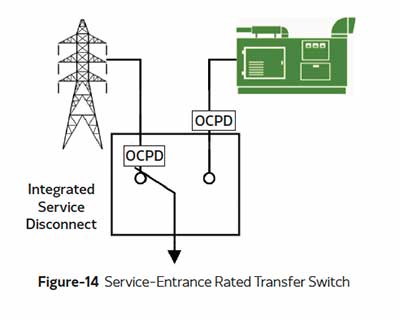

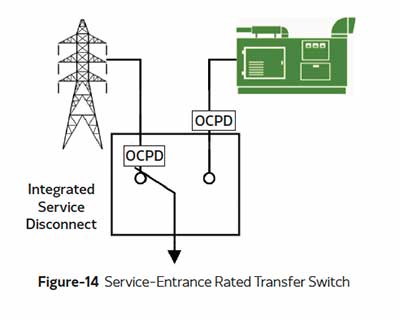

Service-entrance and

non-service-entrance

The National Electric Code requires a way for

disconnecting the electrical service where it enters

a building. Service-entrance rated transfer switches

typically include a circuit breaker on the normal side

which provides for overcurrent protection and a service

disconnect means (see Figure-14). These switches also

include provisions for system grounding and optional

ground fault protection as required. Note that the

withstand and closing rating (WCR) of the switch

might be limited by the OCPD device therefore the

WCR of the switch will be set at Ampere Interrupt

Capacity (AIC) of the OCPD.

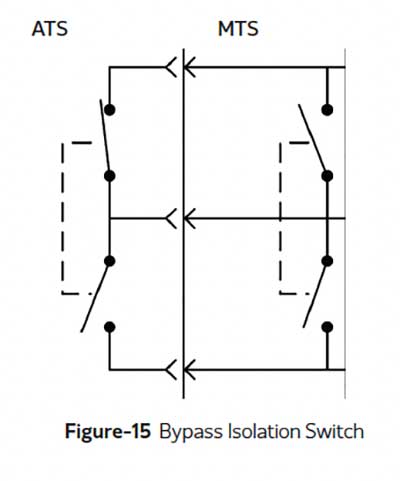

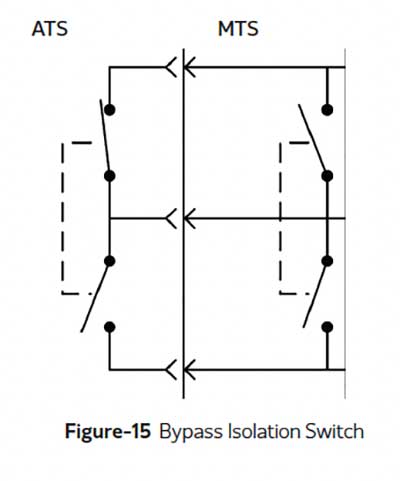

Transfer switch and bypass

isolation switch

Bypass-isolation automatic transfer switch

equipment is a manual bypass transfer switch in

parallel with an automatic transfer switch (see

Figure-15). The parallel connections between the

bypass switch and ATS are made with isolating

contacts such that the automatic transfer switch

can be drawn out for service and repair and power

is fed to the load through the bypass switch. The

bypass-isolation automatic transfer equipment

available from Cummins is the non-load break type

meaning there is no power interruption to the load

when power is switched from the normal path to

the manual ATS path. The manual ATS can also

provide an open transition transfer between the

sources when the automatic switch is not is use.

Voltage and frequency

Transfer switch equipment is available for a wide range of operating voltages at both 50 and 60 Hz. All types of

switches are available for low voltage (600 VAC and below) applications. Typical AC voltages are: 120, 208, 240, 480,

and 600. Also, single and three phase options are available.

The voltage chosen for the transfer switch will match the system voltage for the application, however, withstand and

closing ratings for the switch may vary with its voltage rating. This rating difference can affect the type of protection

equipment required upstream of the transfer switch.

Current rating

Transfer switches are rated for continuous current

which means holding the maximum value for

three hours or more. The continuous current rating

must be selected in accordance with the total

connected load requirements, sized essentially in

the same manner as the circuit conductors. Most

transfer switches can carry 100% rated current

at an ambient temperature of 40ºC. However,

transfer switches incorporating integral overcurrent

protective devices (for example: service-entrance

transfer switches) may be limited to a continuous

load current not to exceed 80% of the switch

rating.

Typically, the most used ampere ratings range

from 40 to 4000 amperes. Switch frame size

dictates the current rating range and the withstand

and closing rating (WCR). Most switches that

incorporate a switched fourth neutral pole utilize

a neutral pole rated the same as the phase poles,

but the manufacturer’s literature should be

referenced to confirm. It is recommended that fully

rated neutrals be used in applications containing

nonlinear loads, where the load induced harmonics

create substantial neutral current. The ampacity

of the switch must meet or exceed that of the

connected conductors.

Future load requirements should be considered

during the planning process and a transfer switch

with a continuous current rating equal to the total

of the anticipated future load should be selected

for the application.

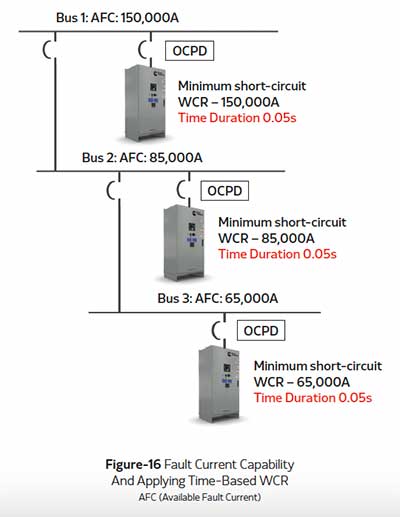

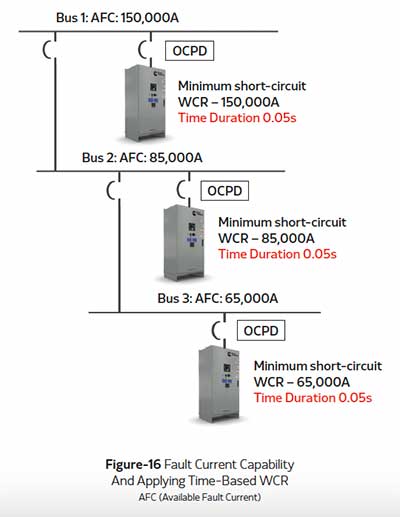

Fault current capability

A fault downstream of the transfer switch will

result in a short circuit current flowing through the

transfer switch. High level of fault currents will

cause thermal and magnetic stress on the switch.

Since transfer switches are not designed to break

(interrupt) fault currents; therefore, they must

be protected by overcurrent protection devices

(OCPDs) on both sources.

To apply transfer switch equipment correctly

within its short circuit or withstand and closing

rating (WCR), it is first necessary to determine

the maximum available fault current from each

source at the switch location. Any potential

contribution from load sources (motors) must also

be considered. Typically, a utility source will have

higher available short circuit current, but generator

sources, particularly multiple generators, must

also be considered. The withstand and close rating

of the transfer switch must be matched to the

available fault current.

All transfer switch equipment is required (per

UL1008) to have short circuit ratings that are

Withstand and Closing Ratings (WCR), which

are expressed in RMS symmetrical amperes at a

maximum system voltage. The WCR is established

by testing only. Calculations of short circuit ratings

have no validity for applications. Rating can either

be time-based or specific OCPD (breaker/fuse)

based. Transfer switches with high time-based

short circuit WCR simplifies breaker selection for

protecting the transfer switch (see Figure-16).

Short-time fault

current capability

Transfer switch manufacturers can take the extra

step and perform the UL 1008 optional shortcircuit

short-time withstand and closing test and

subject the transfer switch to fault currents for

durations longer than what is listed in the UL 1008

standard. Short-time ratings are similar to WCR

ratings,except the duration of the fault is specified

by the manufacturer. For example, Cummins

PowerCommand® transfer switches short-time

WCR are rated to the maximum duration accepted

in the industry, which is 0.5s.

The difference between the short-time rating

and the WCR rating is that the short-time

rating requires that the transfer switch pass a

temperature rise test at rated load after the short

circuit test. What this means is that in order to

apply the short time rating the transfer switch

must still be functional after being subjected to

short circuit current at its short-time rating.

It is important to note that the short-time rating

must be withstand and closing rating. Transfer

switches listed as withstand rating only violate UL

1008 – as the rating is not a true short-time rating

and, per UL1008, shall not be accepted.

A typical application for a short-time rated transfer

switch is when is when it is applied downstream

of a UL1558 switchgear. Since UL1558 switchgear

can have a short-time rating of up to 0.5 seconds.

Another advantage of a high-short rating is

simplifying selective coordination strategies since

the transfer switch can carry that short-circuit of

up to 0.5s allowing downstream breakers enough

time to trip and localize a fault.

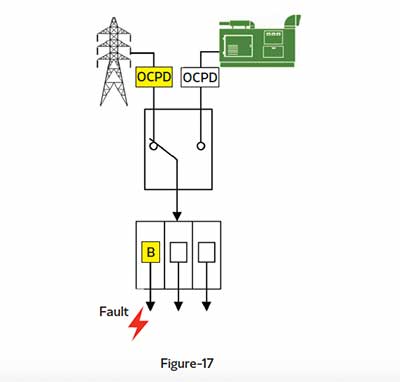

Selective coordination

NEC® defines selective coordination as

“Localization of an overcurrent condition to restrict

outages to the circuit or equipment affected,

accomplished by the choice of overcurrent

protective devices and their ratings or settings.”

Basically, it means that a fault is cleared by the

protective device nearest upstream from that fault

and does not result in unnecessary power loss

to other loads. Selective coordination is typically

achieved by setting the downstream breakers to

trip instantaneously and setting the upstream

breaker to have a delayed trip.

Selective coordination is required for emergency,

legally required standby and critical operations

power systems circuits per NEC®-2020, 700.32,

701.32, and 708.54.

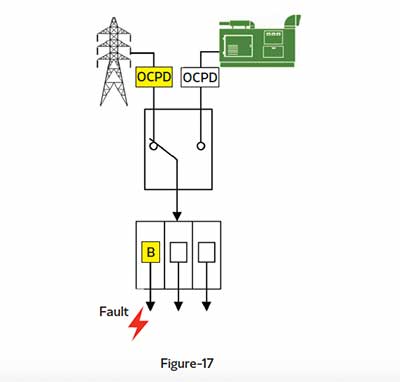

In the example shown in Figure-17, the OCPD on the

utility must trip after circuit breaker B, therefore a

time delay must be set on the utility OCPD. Time

delay setting of the utility OCPD depends on the

available fault current from the source and also on

device B trip curve characteristic.

For the duration of the utility OCPD time delay, the

transfer switch must be able to withstand the fault

and close into the fault. (See Figure-17).

Cable lugs and entry requirements

The typical lug options for transfer switches are compression, mechanical, or no-lugs buss stab only. The no-lugs option is typically seen on high amperage transfer switches, for example, above 1000 amps. All lugs are 90°C rated and accept copper or aluminum wire unless indicated otherwise on the manufacturer drawings. NFPA 70 Article 310 - Conductors For General Wiring outlines conductors ampacity ratings, mechanical strengths, insulations, and uses.

The cable entry areas are also documented on the transfer switch manufacture drawings. The typical entries are top or bottom. It is essential to consider the number of conductors and cable entry early in the design phase to avoid any potential delays or misalignment between, for example, a bottom entry and the concrete pad.

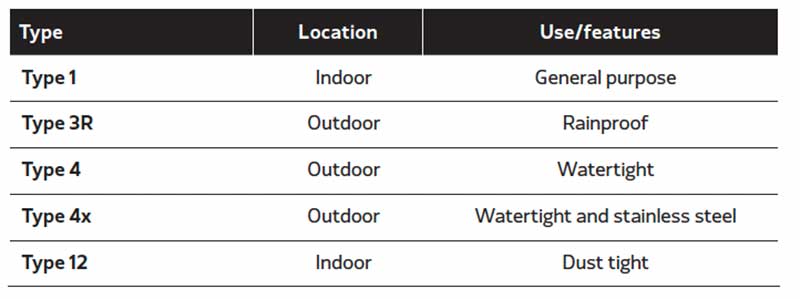

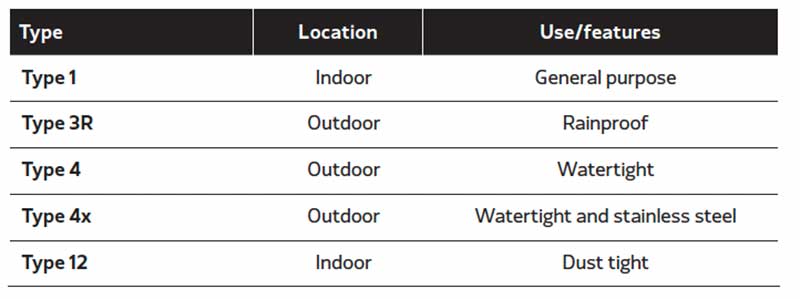

Enclosures

The standard enclosure meets requirements of the National Electrical Manufacturers Association (NEMA 250) and Underwriters Laboratories (UL 50E)

Typically, transfer switch equipment can be located most anywhere in a facility, even outside the facility. However, the location should be chosen to minimize potential damage due to acts of nature (rain, lightning, flooding), or vandalism. Typical NEMA enclosures are:

The enclosure choice is based on placement and environmental conditions. Transfer switches can be configured to include space heaters for outdoor installations where condensation could occur.

Summary

Transfer switches play a significant part in the power system as they are the last link between the power

sources and the loads. Since transfer switches are available in a variety of types, with a wide array of features,

selecting the appropriate transfer switch for a specific application requires a clear understanding of site needs

and application restraints. Some of the critical items to consider when specifying a transfer switch are: codes

and standards, transition type, number of poles, current rating, fault current capability (WCR), short-time ratings,

and grounding schemes. Whether the application is a simple standby power system in a warehouse, a large

emergency system in a hospital protecting the lives of patients, or standby service to a data center handling

millions of dollars in transactions, a careful consideration of the balance between cost, reliability and the quality

of power provided to critical loads is necessary to select the most appropriate transfer switch equipment.

About the author

Hassan Obeid

Sr. Technical Advisor – Power Systems

Hassan Obeid is a Senior Global Technical Advisor of Energy

Management Solutions at Cummins Power Generation

focusing on technical vision, business strategy and solving

a wide range of complex problems.

Hassan has been with Cummins since 2007 in a variety of

roles: power systems design engineering, project engineering

and applications engineering. Hassan has designed power

systems involving switchgear, controls, paralleling, transfer

switches, generator sets, renewable DERs, microgrids and

digital solutions. He has developed and conducted technical

power seminars on several topics and products involving

paralleling, grounding, power systems and controls.

Hassan received his bachelor’s degree in Computer Science

and master’s degree in Electrical Engineering from Minnesota

State University, Mankato.