Parking Garage Maintenance Tips

Effective maintenance routines and readiness to make decisions leads to better outcomes, lower costs, and less stress.

By Annie Celentani, Contributing Writer

Maintaining parking structures at institutional and commercial facilities through wear-and-tear, environmental stressors, and severe weather often falls on the shoulders of maintenance and engineering managers.

Implementing effective maintenance routines and advanced planning can save on costs, minimize disruptions, and improve safety for parking garage users says Jeffrey Elliot, the Seattle branch manager for Western Specialty Contractors, at St. Louis-based company that specializes in masonry, concrete, waterproofing and facades restoration.

“Phased work schedules and off-peak repairs help keep the garage operational,” Elliot says. Timing is another critical factor because “weather and temperature can affect curing times and material performance.”

When starting parking garage restorations or repairs, Western has five main focuses: downtime, timing, safety, long-term durability, and impact.

The company recently restored the parking garage at the Sheraton Grand Seattle. The structure had cracks in the slabs, causing water to flow into the hotel. They restored the garage and a small portion of the pedestrian ramp, removed the existing deck coating and applied a new one, routed and sealed cracks and patched concrete.

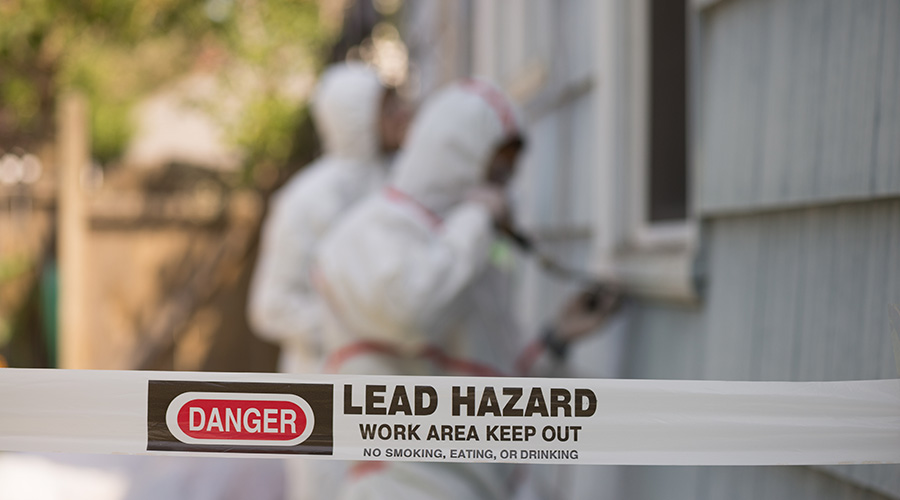

During the process, they protected garage users through using clear communication, signage, and barriers during projects, while focusing on delivering long-term solutions rather than quick fixes.

“Planning the flow of traffic in a parking garage before the bidding process is crucial,” Elliot says. “A plan for managing smells, noise, and dust can make the difference between a great project and a management nightmare.”

Approaching a project

When undertaking a restoration or repair, managers must understand the importance of structural assessment, waterproofing, materials, occupancy impact, and access control.

“Conducting a structural assessment is essential prior to any restoration,” Elliot says. “A comprehensive evaluation by qualified engineers specializing in parking structures will help uncover hidden issues and ensure that repairs are prioritized effectively.”

A leading cause of deterioration in parking garages is water infiltration. To combat this and extend structural life, Elliot recommends ensuring proper drainage and applying waterproof membranes.

Other action items include making sure materials are compatible with the original construction to avoid future issues like delamination or corrosion, planning for material cure times, and confirming products meet VOC, warranty requirements, and durability needs.

Aside from rust, water stains, and ponding, Elliot says managers should keep an eye out for lesser-known problems like cracks, embedded steel corrosion, failed expansion joints, and ventilation issues.

Cracks need attention right away, because they “allow water to penetrate the substrate, leading to freeze-thaw cycles that can harm the structural reinforcement leading to more cracking and spalling,” he says.

Embedded steel corrosion happens when chloride from deicing salts corrodes the rebar inside concrete and weakens the structure, and that “expansion joints are often overlooked but can fail and allow water infiltration,” he says, adding that insufficient airflow can trap moisture and exhaust gases, accelerating deterioration.

Maintenance trumps repairs

Elliot says preventive maintenance is “more cost effective than reactive repairs,” because an effective maintenance routine can help catch problems early. He suggests tracking structural health with sensors or monitoring systems, “training maintenance teams to recognize early signs of damage,” and conducting regular inspections, cleaning, drainage maintenance, and waterproofing inspections.

Monthly visual checks and annual professional assessments “catch early signs of wear, corrosion, or cracking,” and a cleaning schedule that keeps salt, oil and debris at bay “prevents chemical damage and maintains aesthetics,” Elliot says. Staying on top of drain and gutter maintenance can prevent water pooling and freeze-thaw damage, and inspecting and replacing sealants and expansion joints when necessary, maintains waterproofing integrity. If there is a deck coating, “make sure it is not slick and has held up to wear,” he says.

Contractor tips

When choosing a contractor for parking garage restorations or repairs, Elliot suggests finding someone who has a good relationship with the top material representatives and proven experience on similar projects. Specifically, a contractor who wants to be a partner that puts the building first.

A good contractor should communicate clearly and provide detailed proposals, including the “locations of work, quantities included, and coverage rates of the material they intend to use,” he says.

Elliot adds that contractors should mockup the various repair conditions before beginning the project and cover unexpected problems like concrete spalls, cracks, and reinforcement issues.

Vague or overly generic bids, no post-project support or warranty, and a lack of transparency in pricing, material, included scopes of work, or timelines are red flags, Elliot says.

For managers ready to plan a garage restoration, Elliot also offers a money-saving tip: “Consider performing the budgeting and construction during the winter months to increase your chance for better pricing.”

Annie Celentani is a freelance writer based in Milwaukee, Wisconsin.

Related Topics: