« Back to Facilities Management HVAC Category Home

Vacuum Steam Heating: Time for a Comeback?

January 5, 2017

- HVAC

By Igor Zhadanovsky

Near the end of the 19th century, an unknown engineer stood up before a trade association meeting and said, “It is possible that in a few years from now we will be heating … by steam below atmospheric pressure, of such a low temperature that it gives all of the advantages of hot water without any of its disadvantages.” That statement, quoted in “Practical Steam and Hot Water Heating” by A.G. King, may once again be true today.

Vacuum systems were considered to be the Cadillac of steam heating systems (SHS) in the 1900s because of their efficiency and comfort: Back then, conversion from steam to vacuum system saved an average of 35 percent in fuel costs, according to Dan Holohan, “The Lost Art of Steam Heating,” 19th edition. An elegant method was used to overcome the innate problem of uneven heat distribution: instead of pushing air from SHS with 1-2 psig steam, a 6-10 inches mercury vacuum (roughly 3-5 psi pressure drop) is employed in a closed system to pull vapor into radiators quickly, evenly, and at lower temperatures. Vapor in a vacuum travels at impressive speeds — up to 160 miles per hour. An additional bonus is the elimination of air vents, air hissing, and hot water spitting.

In traditional vacuum systems, each radiator is connected to a vacuum pump in a basement, either through a separate line with specialty valve, or through a condensate return line. The condensate return line from each radiator has a steam trap to prevent steam from entering into the vacuum part of the system. Those steam traps became the Achilles heel of vacuum systems — steam passing through the only failed steam trap quickly destroyed thermostatic elements in nearby steam traps, spreading damage further and flooding the vacuum pump with hot condensate and steam. Still, with thorough maintenance, vacuum heating demonstrated wonders in efficiency and reliability — an iconic example is the 80-year-old vacuum heating system in the LEED Gold Empire State Building.

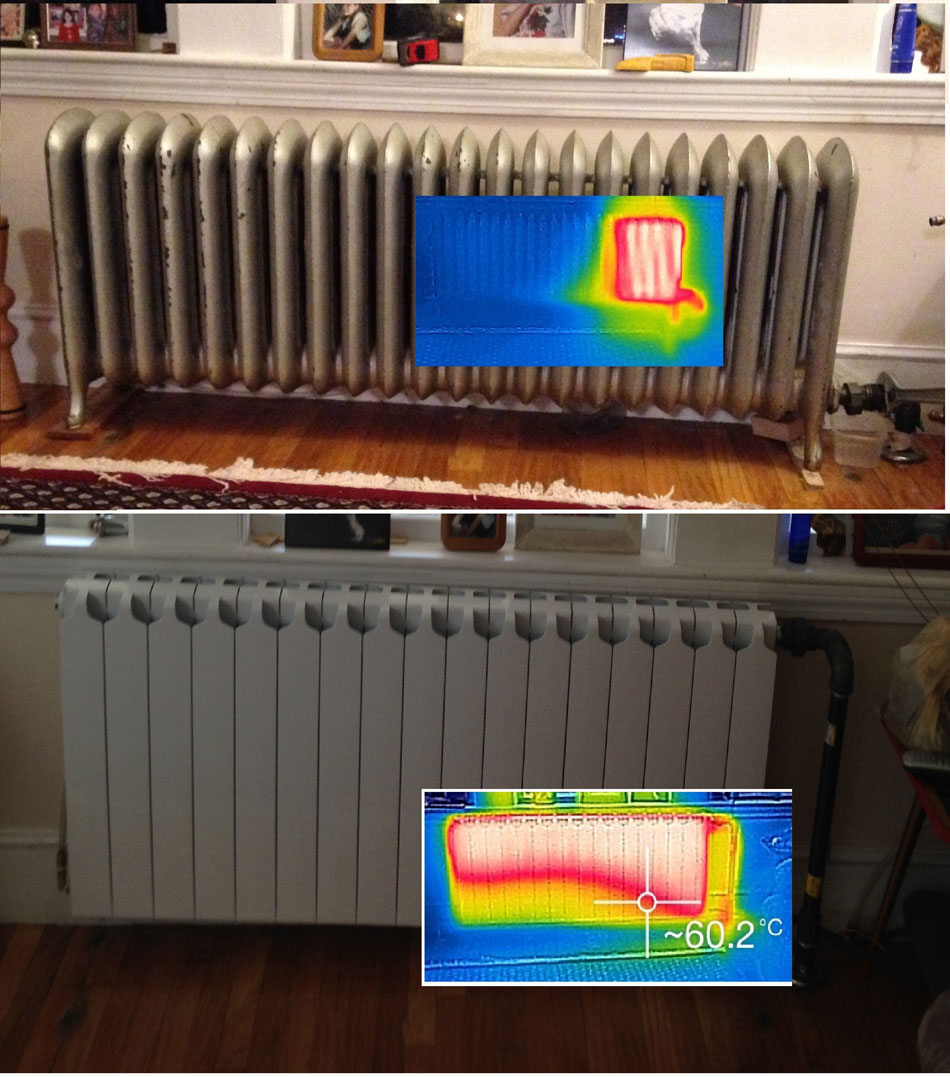

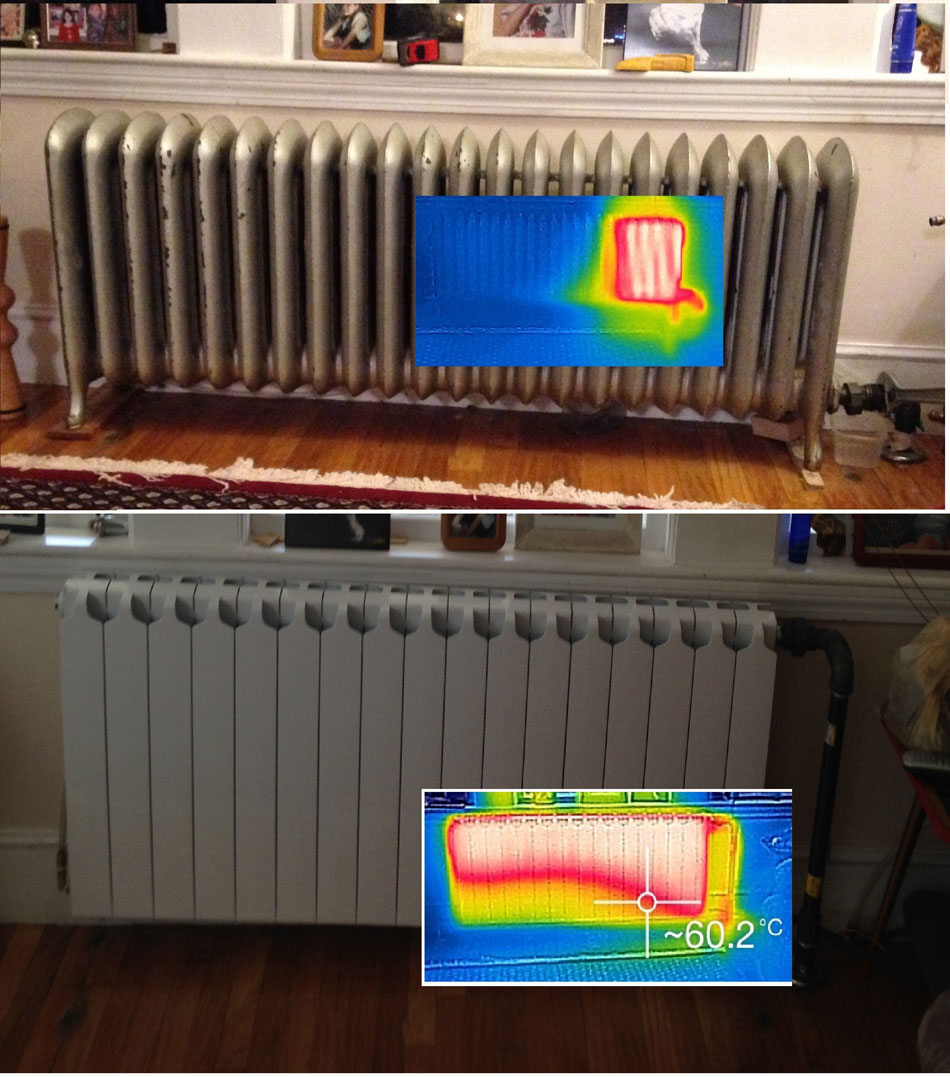

The new vacuum heating system (NVHS) utilizes an innovative control paradigm to eliminate steam traps. A vacuum pump is employed for 1-1.5 hours/day in 3-7 minute intervals, without ever interacting with the hot vapor Smaller diameter tubing and modern plumbing technologies keep the system under a 25-27 inches mercury vacuum, reduce installation time/cost/heat loss, eliminate corrosion, and prevent air leaks. Modern cast aluminum radiators are utilized to save space and improve interior design at a very reasonable price. These radiators heat up quickly and evenly, are warranted for 20 years, and use sections for additions/removals on site. Figure 1 shows infrared images of old and new style radiators after 30 minutes from the systems “cold” start (top — SHS and bottom — NVHS).

Figure 1: Infrared images show the differences between a traditional cast-iron steam heating system (top) and a new vacuum heating system made of aluminum (bottom) after 30 minutes from a cold start.

In new installations, NVHS have the following advantages over hot water systems:

• Health and comfort (radiant heating compared to convection)

• Safety (vacuum versus 30 -100 psig)

• Reliability and low maintenance (minimum moving parts)

• Minimal electricity dependency

• No frozen pipe problems

• No water damage from leaks

• Optional control for either each radiator/zone control, or a combination of both

• No mechanical floors for high rise buildings

Millions of people living/working in old and newer houses have to endure noise, uneven heat distribution, and the low energy-efficiency of their steam heating system. It has been that way for decades, perhaps, from construction and slowly deteriorated with time. Modern hot-water and forced-air heating systems looks appealing, but conversion is too expensive and often not feasible for an aged dwelling; rationales are against investing in an old structure.

A “vacuum boost” for an existing SHS can be done without ripping out old plumbing/radiators/boiler, and with minimal disturbance to tenants. At the beginning of the heating cycle, the vacuum pump creates a 10-18 inches mercury vacuum in the system so water in the boiler evaporates at a lower temperature and evenly fills the system. Steam pressure continues rising, and eventually the system operates at a regular pressuretrol setting of 1-2 psig to prevent air leakage into the system. The boiler continues heating the building until the thermostat switches off. Condensing vapor in the cooling system creates a vacuum naturally, and the boiler provides additional soft heat (which would otherwise dissipate in a basement).

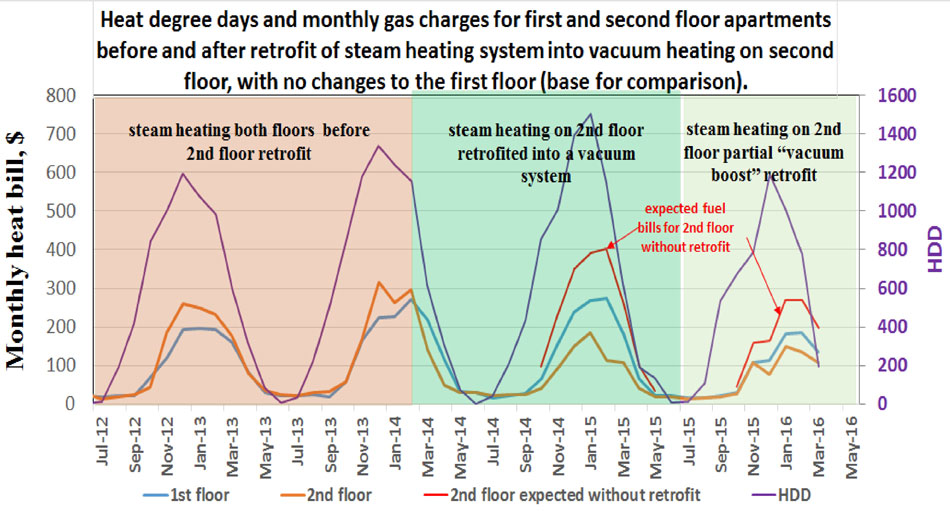

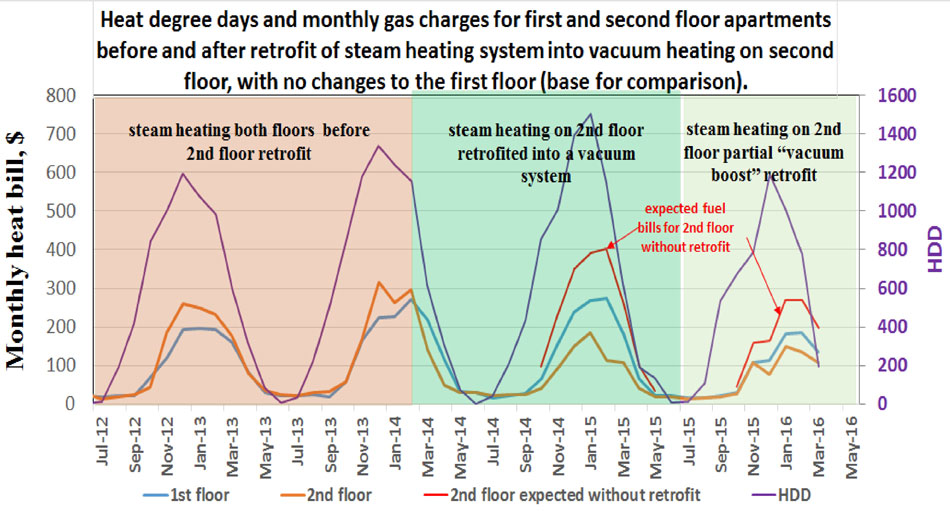

In Figure 2, the annual heat degree days and heating cost data are presented for the retrofit of a single-pipe SHS on the second floor apartment of a two-family house starting in the winter of 2012-13. Because no changes were made to the original single-pipe heating system on first floor, it is used as a base line to compare results. In the winter of 2013-15, a full retrofit into a vacuum system saved roughly 50 percent of fuel gas. A partial “vacuum boost” retrofit saved roughly 30 percent at a fraction (10 to 23 percent, depending on the schematic and condition of SHS) of the full retrofit cost — all materials, tools, and controls are shelf available.

To quote Dan Holohan, the renowned heating expert: “...let’s say you’re in one of America’s older cities and scratching your head over an antique building that has a very confusing steam-heating system. What to do? Of course, you can change parts and make repairs for the rest of your life, or until management tosses you into the street. Or you can suggest management have you rip out everything in the building and allow you to start anew. Another option is to try something new that may at first seem impossible.... It’s a relatively inexpensive retrofit, and it will work in any building without having to tear the place apart. It will even work off city steam.”

Igor Zhadanovsky, president of Applied Engineering Consulting, has worked on steam and vacuum steam systems since 2005. He can be reached at izhadano@gmail.com.