Making the Most of BIM: Clash Detection and Reporting

With BIM, careful coordination between contractor and engineer can make clash detection easier and therefore accelerate the rest of the project.

Building Information Modeling (BIM), as powerful a tool as it may be, is really only as powerful as the coordination between a contractor and an engineer. One of BIM’s most useful functions is the ability to detect and report clashes to the user. Clash detection can accelerate the coordination process between disciplines by identifying issues between models faster and more thoroughly. This allows the communication between trades to focus on solutions rather than identifying problems. The process for clash detection and reporting will vary depending on the stage of the project. In order for building owners and facility managers to receive the most benefit from clash detection tools, they need to understand how the variables and goals in clash detection vary from design to construction phases.

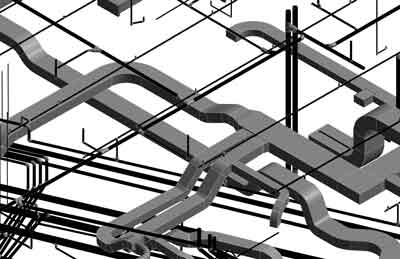

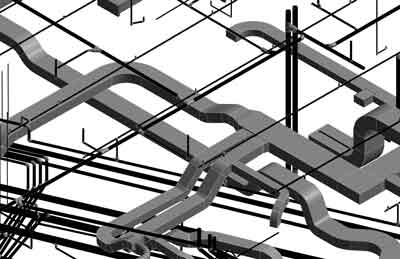

Before examining the differences between clash reporting in certain phases, it is important to understand how BIM models differ during design and construction. Throughout the design phase, the amount and type of elements in the model are prioritized to show the intent of the design, not necessarily the constructability of the model. Design drawings are diagrammatic to show the intent of the design, as are the design models. Design models are typically designed within +/- 4 of uncertainty to assure proper space for construction in the field. For example, pipe hangers and ductwork hangers are necessary pieces for construction but are not shown in a designer’s model because they will cloud the illustration of the ductwork and piping plans. By reviewing the project specifications, a contractor will know what type of hangers to use and how, and the designer will need to allocate space for the hangers for constructability. That is the extent of the modeling completed for hangers. Design times are increased significantly when size, location, and orientation have to be precisely measured.

Clash Detection and Reporting Through the Stages

Although design models may not show every element, clash detection takes on an important role through the design development phase, and building owners and facility managers can reap the benefits from clash detection in the design stages. During the schematic design (SD) stage, clash reports have little to show due to the model’s low level of development. The main benefit of SDs for the owner is that they illustrate the general size of equipment and clearances needed. At this point in the project, the structural design will be close to, if not completely, finished. For example, during the design of a 12 story, 500,000-square-foot medical patient tower, BIM clash detection and reporting were essential throughout the phases of design development and construction design. Bi-weekly clash reports were used in the patient tower design to address structural issues with piping and ductwork. For many projects, this type of reporting becomes an ongoing process throughout the rest of the project.

The patient tower project illustrates a perfect example of a major structural issue. The tower on the east side of the building connected to an existing structure where the floor levels did not align perfectly with the floors of the tower. This created the need for ramps between the existing and new construction, resulting in structural beams being placed lower than normal. Large duct mains were shown penetrating the low beams as well as smaller branch ductwork. If this were not caught in the clash detection process, ceiling heights during construction would have been lowered below eight feet to allow ductwork to pass through, causing complications. Instead, the issue was caught in time to make major changes to the layout of the ductwork, allowing for smaller ducts to cross the tighter areas.

The construction document (CD) stage is where the most value comes out of clash reporting. All disciplines become more finalized as the project progresses, and due to the higher level of development, more test parameters can be created to catch clashes of pipe-to-ceiling, pipe-to-walls, pipe-to-ductwork, etc. At this point, input can be given on how a maintenance team would access and work on each piece of equipment.

Owners can ask for and see confirmation of ceiling heights, and any project where a ceiling space has coordination issues cannot be guaranteed to fit within the space in which it is shown. Access locations and equipment egresses can also be confirmed by modeling the paths and clearance spaces needed. In the case of the aforementioned patient bed tower project, large switchgears were located in an interstitial level with low floor-to-floor heights. Owners expressed concern over the ability to remove the equipment at the end of its lifespan. Using the width and height of the switchgear while being carried on a lift, the egress path was modeled with an extrusion of the same height and width. Clash detection was then implemented to analyze pinch points that would block egress.

(Modeling hangers is practical in the construction phase for the purpose of coordinating hanger locations with routing of the surrounding systems, while providing adequate support for its own system. Conduit is modeled in this phase as well.)

(Pipe and ductwork hangers and conduit are not shown in a designer’s model because they will cloud the illustration of the ductwork and piping plans.)

Related Topics: