Snow management

By Dave Lubach, managing editor

September 2022

Sustainability and snow and ice management are two terms that have recently become interconnected as a forward-thinking strategy known as sustainable winter management (SWiM). As the expectations, costs and environmental effects of snow and ice management services increase, grounds managers are looking for more sustainable practices for their exterior services. In many cases, exterior services directly impact interior conditions, which ultimately affect bottom-line costs.

The additional stresses winter weather causes managers are unlike those experienced inside buildings. Cost control, risk management and rising expectations for near perfect conditions are typical challenges managers face.

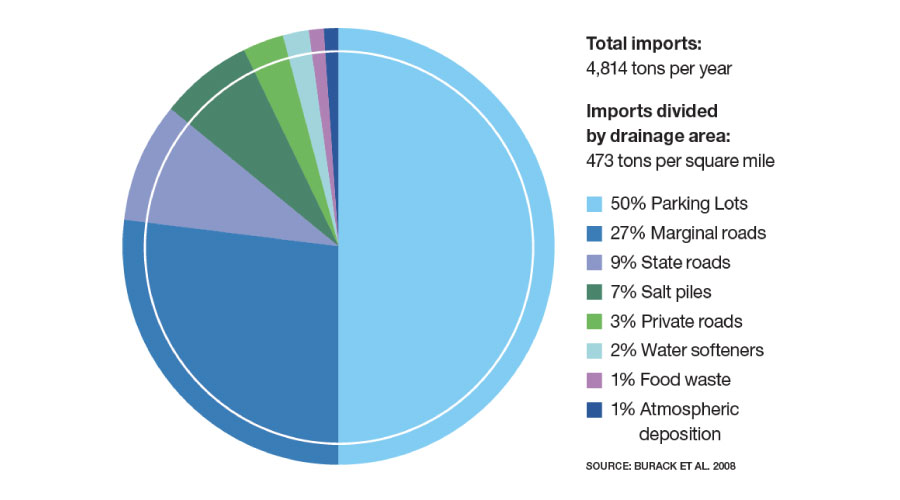

Liability linked to the overuse of de-icing salts, such as rock salt or sodium chloride, is a challenge more managers will face in the coming years. Multiple research studies have validated that most of the non-point source chloride contamination of freshwater bodies and aquifers originates from parking and sidewalk surfaces as shown in Figure 1. Managers need to be prepared for future regulations and liability linked to their use of de-icing salts to control slippery winter conditions.

Standards and processes

To address these and other challenges, managers can use the (SWiM) standards system. SWiM is an industry-established set of policy and practice standards for conducting responsible snow and ice management. The genesis of SWiM standards includes a two-year Harvard University study of the drivers and variables that influence the amount and frequency of road salt application, in addition to identifying the comprehensive list of snow and ice management best practices.

The results of the Harvard research revealed a framework of best practices and solutions interventions that evolved into the SWiM standards for managers in institutional and commercial facilities to follow. Unlike other sustainability initiatives that typically cost more money to initiate, the benefits provided to properties that follow SWiM standards guidelines include saving money, managing risk and reducing salt use, which naturally benefits the environment and managers’ reputations.

A case study conducted at Rochester Institute of Technology (RIT) validates that implementing SWiM guidelines produced significant results in cost efficiencies, reduced salt use and increased environmental responsibility. Beyond these immediate results are the anticipated long-term benefits to a property’s infrastructure.

Although SWiM certification audit guidelines include more than 100 criteria that must be met for facilities to earn SWiM certification, the broad criteria of policies are available for any manager or public organization to apply. These straightforward categories of policy enable standards of practice for in- house, contracted, or public winter maintenance operations, as shown in Figure 2.

Categories within the SWiM process include:

Measure: Anything that is measured can be improved. Managers can measure parking lots and sidewalks and compare them with industry production rates guidelines published by the Snow and Ice Management Association. These guidelines include examples of average times required for plowing 1 acre of parking lot, shoveling 1,000 linear feet of sidewalk and the average quantity of time and salt required for anti-icing and de-icing applications.

The Sustainable Salt Initiative has established salt application rate guidelines. It is important to always measure surface temperatures, not air temperature, when deciding application rate guides to use.

Managers can measure salt application rate output on a per-application basis. Salt measuring technology and cloud-based, GPS-enabled tracking software can make measuring salt applications easier and more affordable.

Managers also can measure the level of service expectations and results using site weather cameras or assigning someone to visually observe and document snow operations, including pictures to reference. It is important to understand when the level of service expectations is being met and when they are being exceeded, which typically includes over-applying salt.

Calibrate: Salt-application equipment should be calibrated to confirm minimum and maximum material flow rates. Calibration should be performed pre-season and mid-season at a minimum. Re-calibration should also be performed anytime a repair or other changes are made to the salt-application equipment.

Calibration of storm response times with resource allocations such as quantity of people, materials and equipment, is also important to practice. Timing of storms and accumulation thresholds, compared with shift schedules, for example, are important to establish.

Prevent: Technicians can prevent the bonding of snow and ice on paved surfaces by incorporating anti-icing application techniques as a standard of practice when conditions allow. Although dry salt applied as anti-icing can be effective, liquid salt brine is the recommended method to prevent dry salt bounce and scatter waste.

When outsourcing snow and ice management to contractors, managers can prevent the overuse of salt with service contract terms that incentivize efficiency rather than charge by the amount or the frequency of service and materials used.

Analyze: Analyze inconsistencies with plow production and salt application rates by categories of variables including:

- parking lots and roads

- Trucks and utility vehicles

- equipment, including spreader type

- operator or driver.

Managers can perform this analysis by using GPS-enabled technology and salt tracking hardware that is readily and affordably available.

Improve: Managers can improve salt rate output by analyzing inconsistencies of measured salt application rates. They can identify the lowest measured rate that achieves the desired level of service and recalibrate salt application equipment to the lowest successful rates.

Improved production cycle times can be achieved using site maps and scheduled training with operators on ways to best route a site or a portfolio of sites.

Optimize: Technicians can optimize dry salt output by pre-wetting dry salt flow with salt brine at the spinner of the spreader. Salt is only effective for melting snow in its liquid form which is brine. Pre-wetting dry salt with a small quantity of brine helps expedite the desired brine reaction.

New segmented plow technology enables greater efficiency for clearing snow from parking lots down to near bare conditions. Less snow and ice accumulation on the parking lot surface means less salt is needed to melt them.

Site analysis

The RIT case study of SWiM-certified sites conducted to assess multi-location retail properties located in the snow belt of Upstate New York validated significant cost, risk and environmental benefits. It compares two sets of retail store properties owned and operated by the same company with virtually the same parking space quantity and footprint and located only a few miles from each other.

Dave Lubach, Managing Editor, Facility Market